* Material: Glass

* Color: Black, white (customizable)

* Size: Customized according to customer requirements

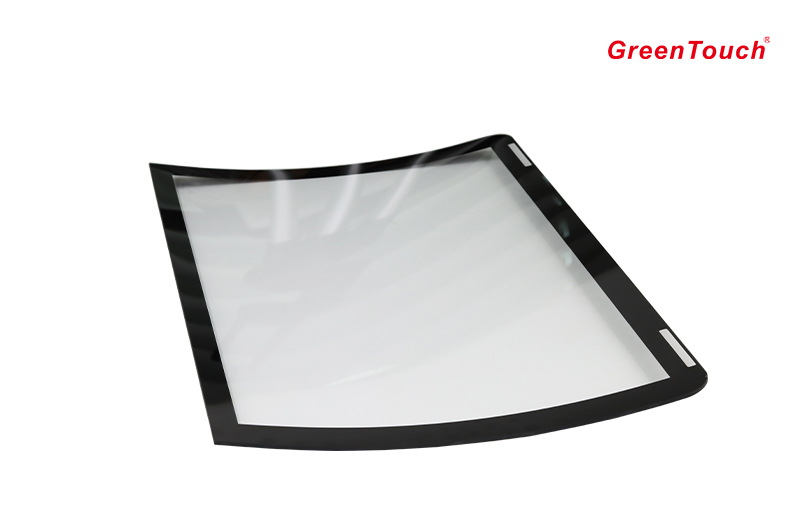

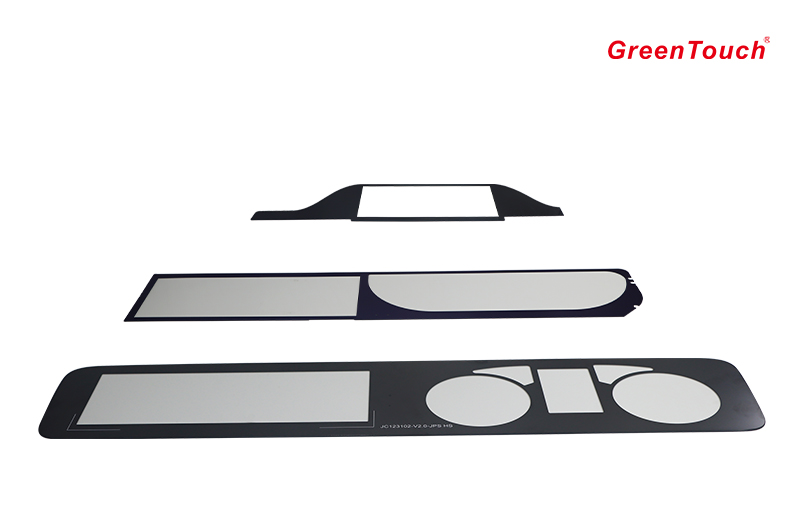

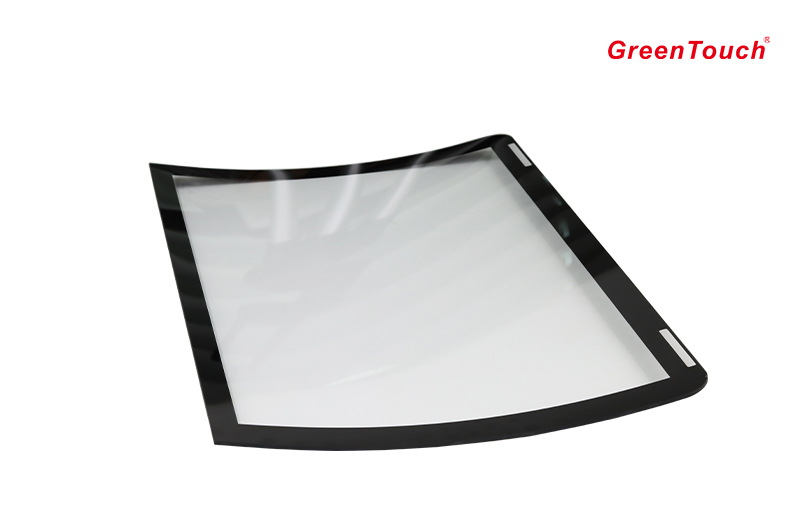

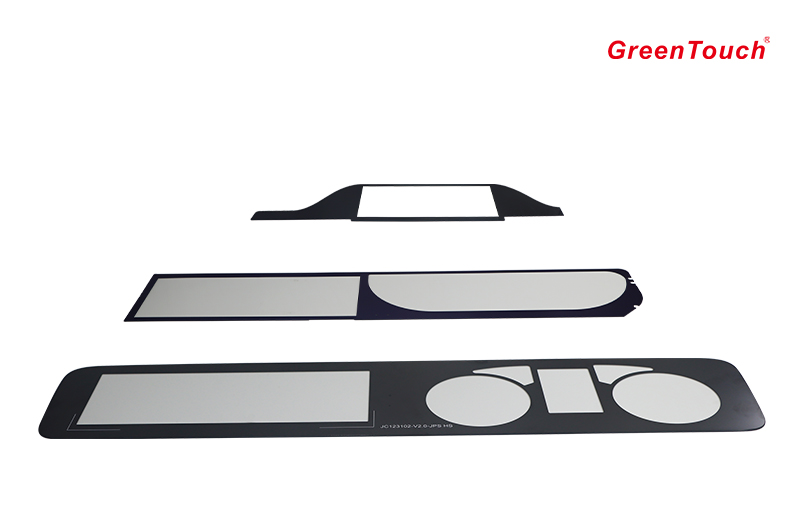

* Shape: Round, square, rectangular, irregular, customizable according to drawings and samples

* Processing: Carving, edge grinding, polishing, tempering, silk screen printing, drilling, laser engraving, adhesive backing, etc.

* Turn: 10 days, customizable according to drawings and samples, processing with supplied materials

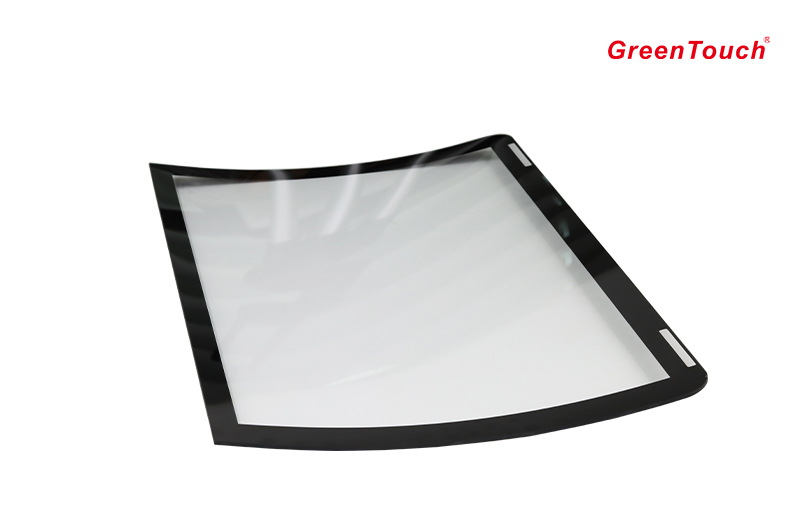

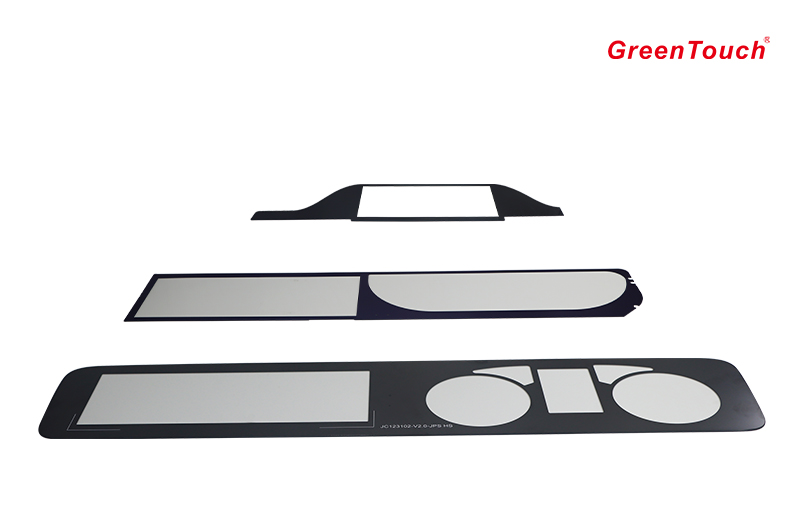

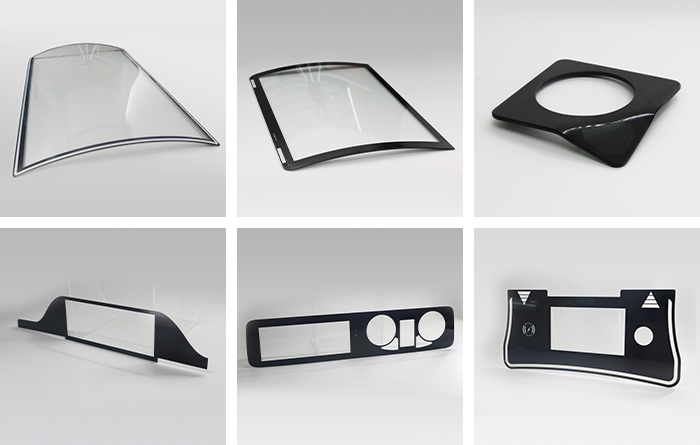

The special-shaped screen is a screen with parts cut off from the non-special-shaped screen. It can be cut into various irregular shapes to display some creative content to meet the needs of various scenarios. GreenTouch has more than ten years of experience in the touch screen industry and can provide customized services for special-shaped glass cover screens of any size and shape. If you need it, please consult professional customer service.

(1) Safety: Once local damage occurs, stress release will occur and the glass will be broken into countless small blunt-angle particles. These small fragments have no sharp edges and are not easy to hurt people, and will not cause serious harm to the human body.

(2) Thermal stability: Tempered glass has good thermal stability. The temperature difference that tempered glass can withstand is 2 to 3 times that of ordinary glass, and the maximum operating temperature is close to 250°C.

(3) Surface stress: 69~168MPA. Physical tempered glass has a special stress structure, which allows the fragment area to remain within the frame when it is damaged, and has a certain impact resistance.

Can customize square,round,trapezoidal,hexagonal,triangular,spliced tempered and other special-shaped glass (can be customized according to drawings)

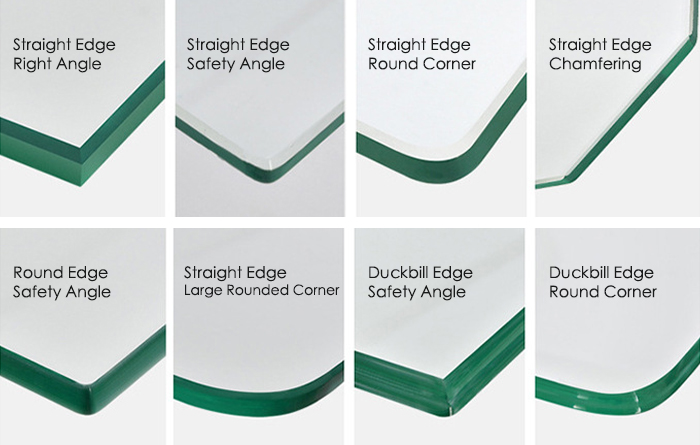

Edge processing technology: straight edge, round edge, duckbill edge, etc.

Corner processing technology: right angle, safety angle, rounded angle, cut angle, etc.

Can perform glass cutting, fine carving, edge grinding, tempering, silk screen printing and other processing technologies

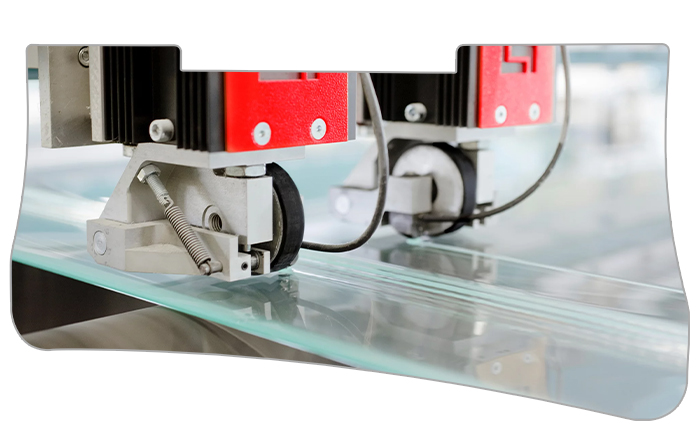

Glass cutting: The original glass is cut into glass of the same size according to the customer's drawings. The automatic cutting machine can make the glass size accurate, without edge collapse and distortion.

Glass fine carving: The computer-aided design system is used to grind, cut, punch and polish the glass.

Glass edge grinding: The cut glass is edged to prevent the glass from cutting hands.

Glass tempering: The glass is treated at high temperature in the tempering furnace to increase its hardness and make it less likely to break.

Glass silk screen printing: Silk screen printing patterns are processed on the glass surface according to the customer's pattern and LOGO.

| Type: | Glass cover plate special-shaped screen |

| Size: | Customized according to customer requirements |

| Shape: | Round, square, rectangular, irregular, customizable according to drawings and samples |

| Color: | Black, white (customizable) |

| Material: | Glass |

| Processing: | Carving, edge grinding, polishing, tempering, silk screen printing, drilling, laser engraving, adhesive backing, etc. |

| Turn: | 10 days, customizable according to drawings and samples, processing with supplied materials |

Application Scenario

|  |  |  |

| Membrane Switch Panels | Electronic Product Panels | Medical Equipment Panels | Smart Home Appliance Panels |

|  |  |  |

| Wireless Power Bank Panels | Charging Pile Panels | Beauty Instrument Panels | Equipment Instrument Panels |

Add:Floor 3, building A2, silicon valley power low carbon technology demonstration park, Guiyue Road, Zhangge community, Guanlan Town, Longhua new area, Shenzhen