2022-08-05 11:26:59 1832

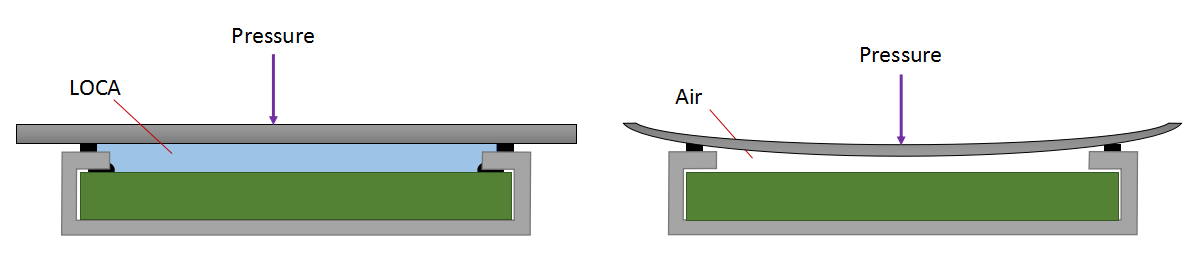

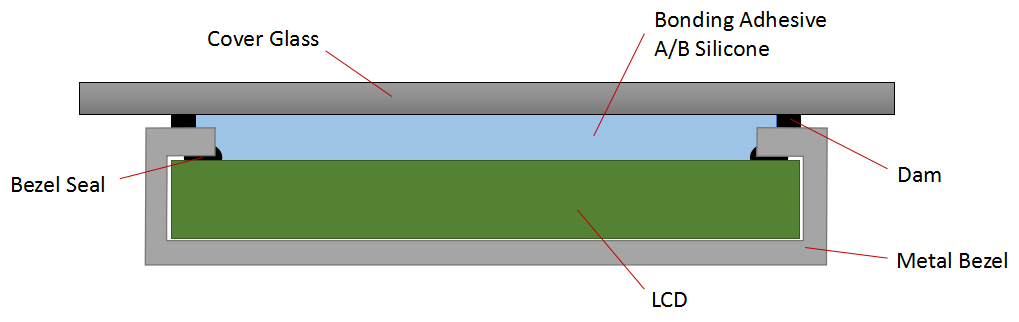

Basic Product Setup

Comparison Air Gap – Bonded Display

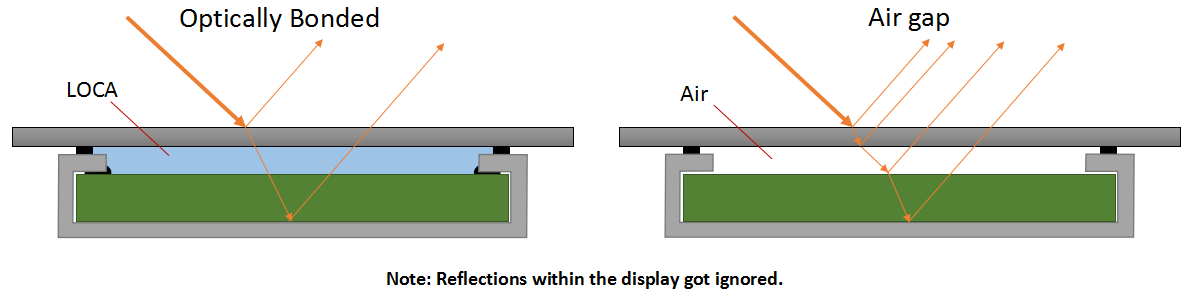

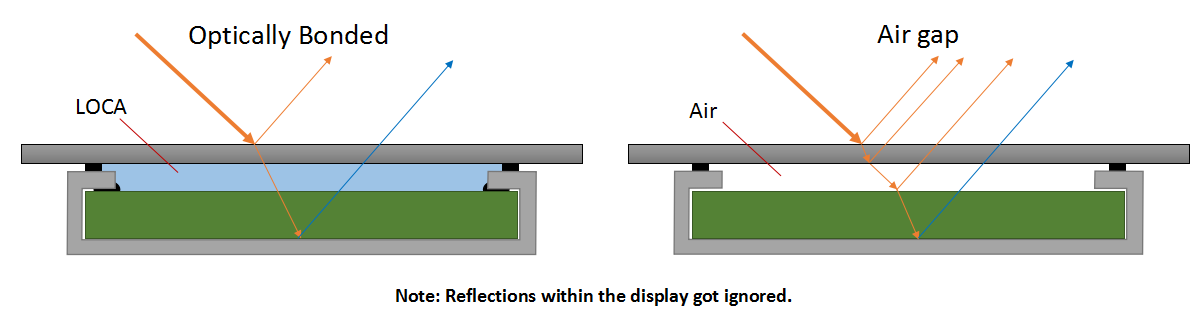

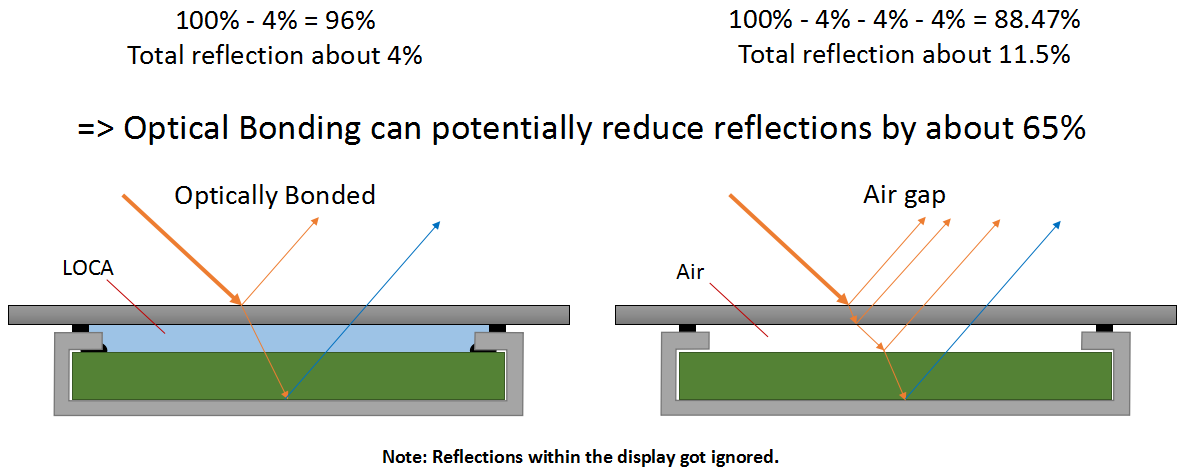

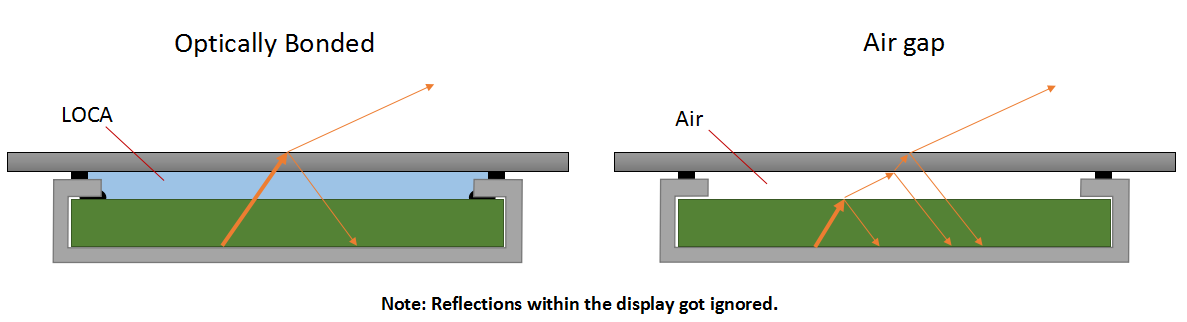

Reflection:

Every time light goes from one material into another one having a different refraction index, about 4% of the light will get reflected. Bonding the cover glass to the display will prevent the reflection at this position.

Reflection:

Due to reflections within the display (indicated in blue) will path the LC panel again they don’t have negative influences and can be ignored.

Reflection

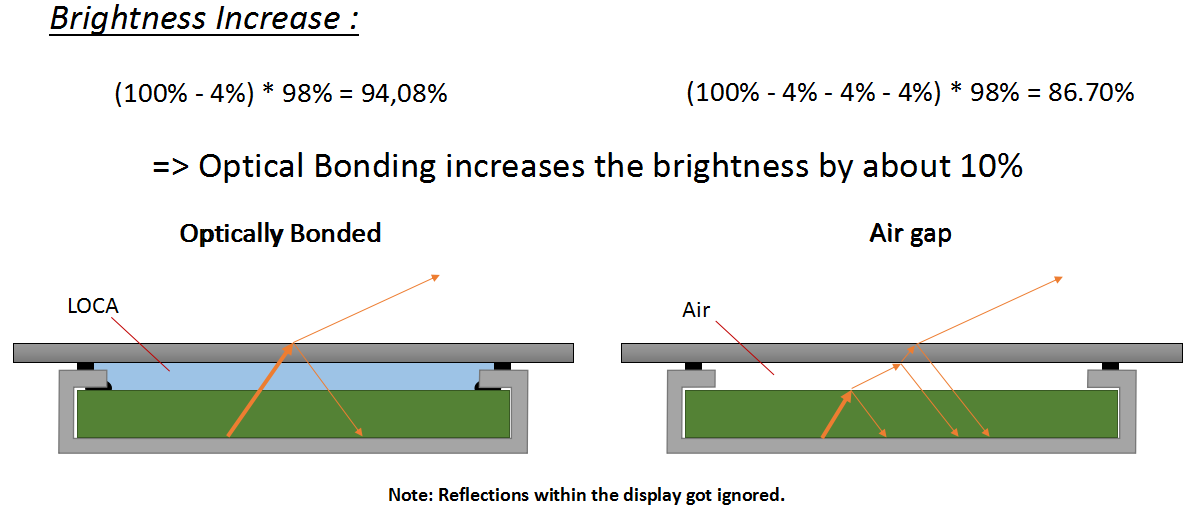

Brightness Increase:

Putting a cover glass on top of a display reduces the products brightness due to reflections of the light coming from the backlight as well as the glasses transmission (usually about 98%).

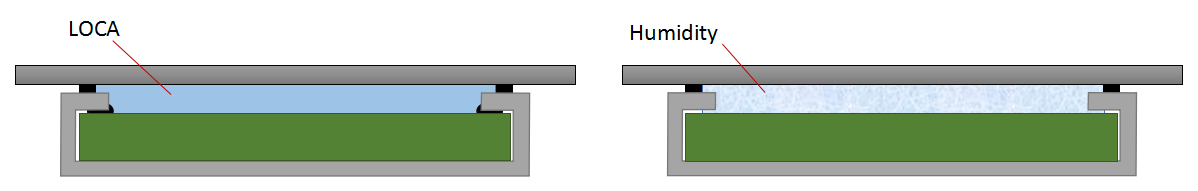

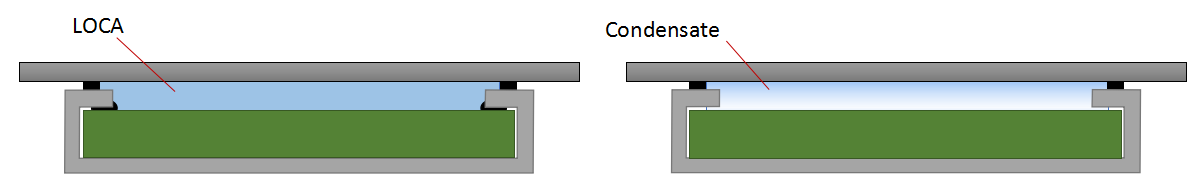

Fogging:

Depending on the location and season the amount of water in the air can variate from 10% up to 100% RH. This humidity will also be contained inside the air gap. In case of optical bonding there is no air and so also no humidity between glass and display.

Fogging:

Deviations in temperature or air pressure can cause the humidity to condense on the surfaces. Especially in sealed system where air cannot circulate anymore fogging of the glasses inner side is very likely to happen.

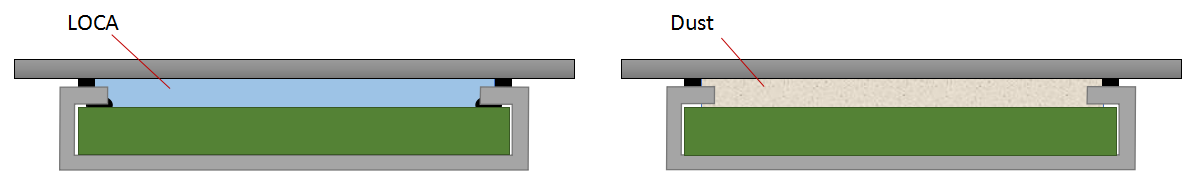

Dust:

Systems which do not require air tight sealing are less prone to fogging. Therefore circulating air can bring dust into the air gap. These particles might be visible and will become more and more over the products life time. Especially products for industrial applications often operating in dirty environments are susceptible.

Ruggedizing:

Filling the air gap with silicone gives additional strength to environmental forces which otherwise could brake the glass. At the same time the silicones elasticity is still sufficiently to absorb shocks.